Landfill managers know the amount of incoming waste quite well, but all waste is not created equal and comparing only the daily incoming tonnage can be misleading. Getting to know your hourly input tonnages by waste stream and peak hours will help you to choose the right size of compactor.

Why size matters?

The operating weight determines how much waste a compactor can process and compact. The heavier the operating weight of a compactor is, the more waste it can compact in one pass, thus compacting more waste per hour. If the compactor is too small, it can’t process incoming waste quickly enough, resulting in stoppages or clogging of the waste input. For every minute that incoming waste waits to be unloaded, revenue is lost.

Heavier landfill compactors cost more to purchase and operate. Maximizing revenue is, therefore, not based on getting the biggest landfill compactor, but rather the correct size for your needs.

How do you know the right size for a landfill compactor?

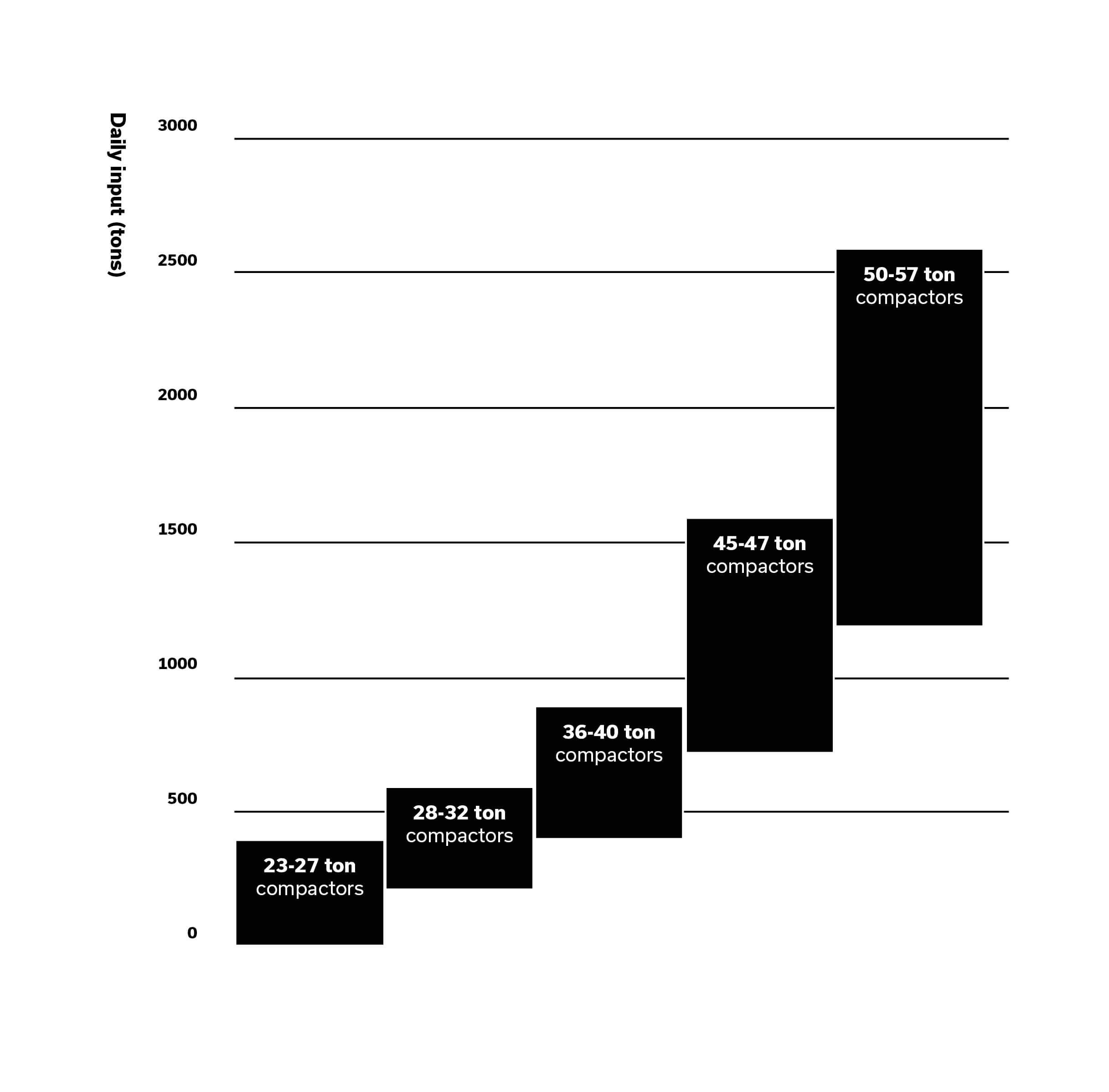

A landfill compactor’s theoretical capacity can be calculated based on its operating weight and width. For example, a landfill compactor with an operating weight of 32 tons should be used to compact 200–650 tons of waste per day. This is called a theoretical capacity because to achieve the maximum number of compacted tons, the waste needs to come in at a steady and optimal rate and be ready to be compacted without any additional work phases such as spreading it.

Operating a landfill compactor at the upper limits of its capacity is not optimal. A 32-ton compactor can compact 20–65 tons of waste per hour. It can handle 65–85 tons per hour when needed, but continuous operation at the upper limit increases wear and shortens the service periods. So, choosing a landfill compactor that will work at its optimal range most of the time is smart business.

In real life, the amount of waste coming in can vary a lot. These peak hours can exceed even the maximum capacity of a landfill compactor but don’t show up when looking at just the daily input. If the site can be organized in a way that the excess waste can be dumped and spread ready for later compaction, there is no problem. However, on many landfill sites, during the peak hours the trucks bringing in the waste will simply have to queue and wait for their turn to unload. This reduces the profitability of the whole operation.