Our comprehensive services offer a tailored approach to extending and enhancing the life of your TANA machine, ensuring it meets both current demands and future challenges.

REFURBISHMENT

With Refurbishment, we meticulously clean and restore your machine to maintain optimal functionality, providing a cost-effective way to extend its lifespan.

Example – Rotor refurbishment

We offer expert rotor refurbishment, restoring rotors to near-original condition with original parts and professional precision. Additionally, rotors can be customized to 33 or 44 teeth, enhancing shredding performance to meet your needs.

REBUILD

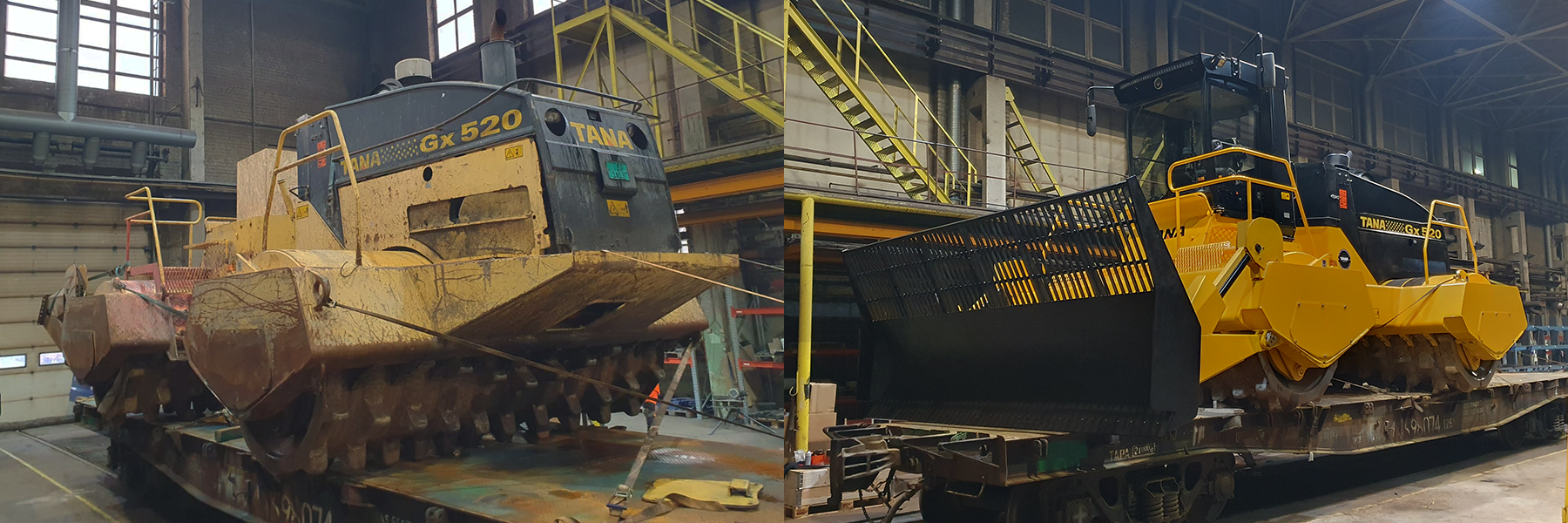

For equipment in need of more extensive attention, our Rebuild service fully restores performance to its original level, making it a sustainable choice for giving your machinery a second life.

Example – Machine rebuild

For example, a used TANA shredder can be fully rebuilt with new wear parts, modernized electronics, and factory-tested reliability – giving it a second life at a fraction of the cost of a new machine.

COMPONENT REBUILD

Our Component Rebuild option focuses on specific parts, rejuvenating them to a like-new condition, which bolsters the machine’s durability and longevity.

Example – Component rebuild

For example, a rebuilt rotor for a TANA shredder undergoes thorough inspection, replacement of worn elements, and reassembly to meet original factory specifications.

UPGRADE

Finally, our Upgrade service goes beyond simple restoration, enabling performance enhancements that allow your TANA machine to adapt seamlessly to new operational needs, ensuring it continues to deliver robust performance in a changing environment.

Example – Upgrade kit

If your magnet conveyor has reached the end of its life and requires repair, the Upgrade Kit provides all the necessary 14 parts to restore your conveyor to optimal working condition. This ensures efficient metal separation and ongoing protection for your recycling process.

Got questions? Contact our Tana Second Life Team!

Looking for Rebuild Partner in North America or Canada? Please contact our authorized distributor Humdinger Equipment