Rubber waste originated from car and truck tyres is almost equal in heat value as gasoil and even 25% more effective than coal. There are extremely high-quality requirements for the rubber waste used in the burning process at power plants. The particle size needs to be homogenous and no remnants of metal wires are tolerated in the furnace.

Quality issues in particle size as well as ineffectiveness in the shredding process were the Achilles heel for our customer Lassila & Tikanoja Ltd (L&T) who provides rubber waste for the energy industry. L&T has operations in Finland, Sweden, Latvia and Russia.

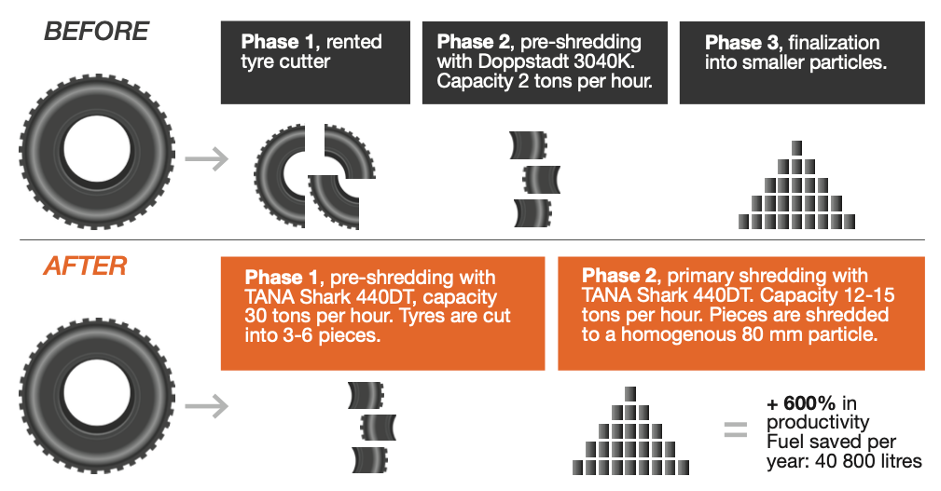

Earlier, the process of shredding car & truck tires at the L&T site was done in three separate phases. First, tyres were ripped up with a rented tyre cutter. Secondly, tyres were pre-shredded with Doppstadt 3040K. After these phases the particle size was still not homogenous enough. For that reason, the material needed to be processed an additional third time in order to achieve the required 80 mm particle size and make sure that the end result is pure rubber without any metal wires.

Faster process, higher quality and less expenses

After purchasing the TANA Shark 440DT the whole tyre shredding process at the L&T site is now handled with one single machine. Figure 1 below illustrates the change of shredding process after purchasing TANA Shark 440DT at the L&T site in Turku, Finland.

“One of the key issues to purchase TANA Shark 440DT was the fact that the machine is able to shred not only tyres but also plastic waste, plastic rolls, mattresses and MSW”, L&T Finland Production Manager.

As demonstrated above, TANA Shark 440DT takes care of the whole shredding process in two phases. During the pre-shredding phase the whole car & truck tyres are cut into 3-6 pieces. This also loosens the metal wires inside the tyres. In this process the machine is driven with all counter-knives, without screen and without the over-band magnet.

In the primary shredding phase unwanted metal wires are removed by using an over-band magnet and the 170 mm screen is inserted below the rotor to generate the wanted homogenous particle size of 80 mm.

You can customize the TANA Shark with different rotor screens to create particle sizes from 50 to 500 mm. Adding or removing the rotor screen can be done in only 10 minutes.

”What has amazed us is the fact that using a single machine gives us the required end result. If possible, even more amazing is that this is achieved with 5-10 litres lower fuel consumption per hour than before”, says Production Manager.

The TANA Control System gives L&T the ability to adjust and monitor the usage of the machine. Pre-programmed settings have been really helpful for them in monitoring and controlling the fuel consumption.

”What we have learned is that using 75% of the maximum power and torque for tyres gives us the best operating efficiency”, says Production Manager.

Did you know?

With the total consumption of 25-30 litres per hour, TANA Shark is the most fuel-efficient tyre shredding multi-use unit on the market.

About Lassila & Tikanoja Ltd. (L&T)

L&T specializes in environmental management and property plant support services and is a leading supplier of wood-based biofuels, recovered fuels and recycled raw materials. With operations in Finland, Sweden and Russia, L&T employs 8,200 people. Net sales in 2019 amounted to EUR 784.3 million. L&T is listed on Nasdaq Helsinki.