Shredding end of life tyres in one pass

End-of-life tyres for cars, trucks, aircraft and heavy-duty vehicles are among the most problematic and difficult waste types to recycle. Impossible for other shredders with the same fuel efficiency and capacity, TANA high-torque shredders make it possible to shred tyres to a very homogeneous 80 mm (3″) particle size in just one pass and separate most of the metals during the shredding process. An overband magnet separates most of the metal wires directly from the shredded material flow on the conveyor. Once separated, shredded tyres and metals can be sold and reused in many ways.

The particle size can be adjusted by changing the counter-knife setting on the side door and choosing a suitable rotor screen. The bigger the particle size, the higher the capacity. By using the operating program for tyres, the machine automatically adjusts itself to the optimal level, thereby protecting the machine and optimizing operating costs.

How to generate income from end of life tyres?

Tyres as an Alternative Fuel in cement kilns

End-of-life tyres pose recycling challenges due to shredding costs, but tyre‑derived fuel (TDF) offers a strong alternative to conventional kiln fuels. TDF’s calorific value is nearly on par with oil and about 25% higher than coal—plus, it’s cheaper—making it economically attractive. Compared with refuse-derived fuel (RDF) or solid recovered fuel (SRF), TDF is more consistent, simplifying combustion control.

With growing tyre waste and landfill bans, TDF represents a readily available resource globally. Its use in cement kilns also reduces nitrogen oxide (NOₓ) and particulate emissions, decreasing urea needs during production.

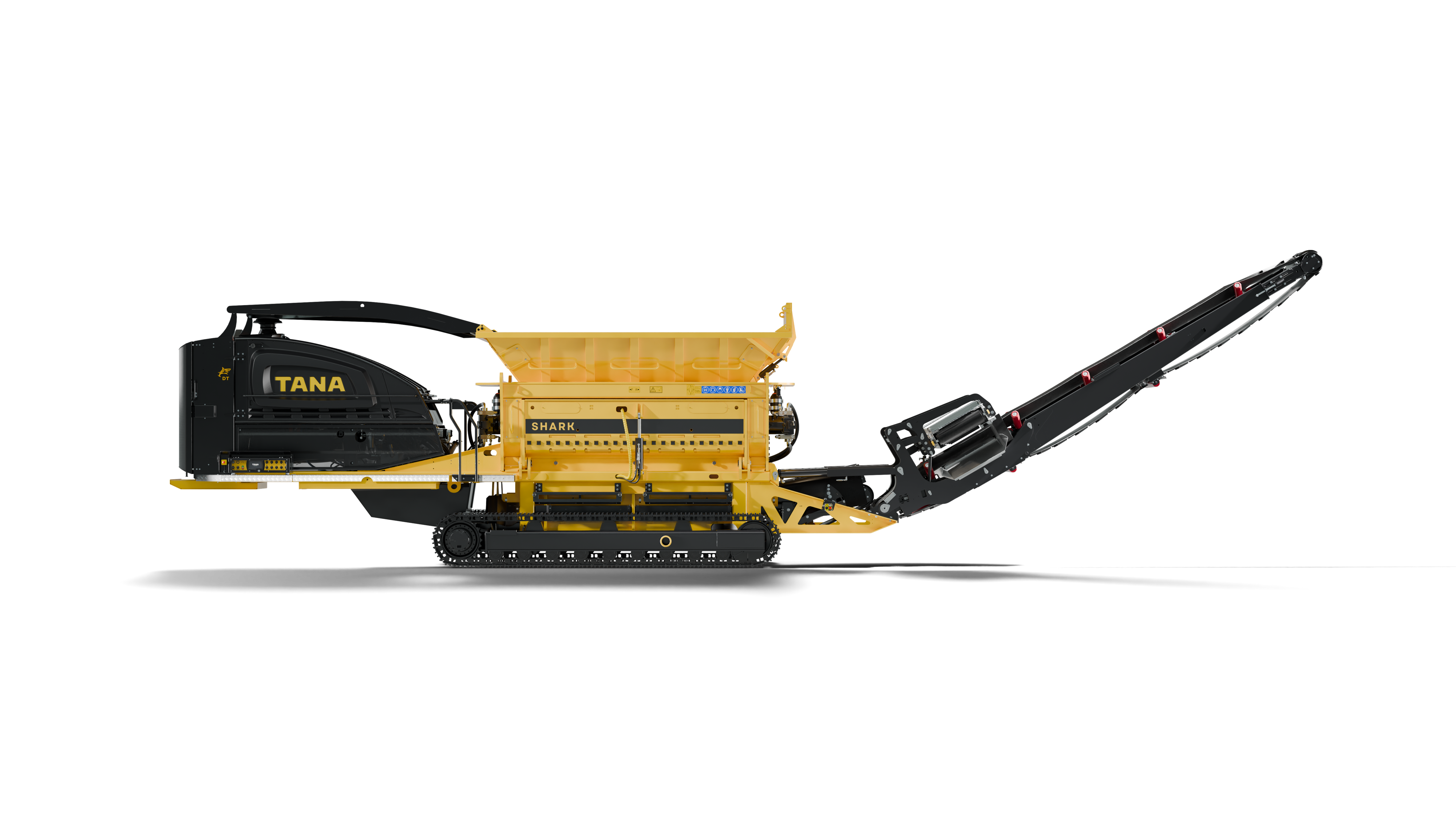

TANA Shark for processing tyres

The TANA Shark shredder is optimal for producing TDF:

Tyre-derived fuel delivers cost savings, consistency, and emission benefits when used in cement kilns. The TANA Shark streamlines TDF production with flexible sizing, steel handling, and multi-waste capability—making it an efficient one‑machine solution.